Mango Materials: The Future of Plastics

International Speaker Annabelle Williams, Reaction Founding Partner and Head of Communications, spoke with Molly Morse, Co-Founder and CEO of Mango Materials.

Reaction Catalyst - Molly Morse

Reaction Catalyst is an event series that connects the worlds best innovators, promoting solutions with global potential, with a global community of leaders, offering the influence to realize it.

Ambitions to go green are everywhere. Companies and governments have sponsored unprecedented budgets and have publicly communicated their bold visions for a better tomorrow. Despite the exponential demand, supply of solutions that are ready to scale is extremely limited.

The mismatch between demand and supply has outspread so far, in fact, that The Economist highlighted the green boom bottleneck in its cover story last June.

Reaction searched for an innovative leader and company who were positioned to scale a solution. One that could make green ambitions become a reality. Reaction invested in Molly Morse of Mango Materials. We are excited to share her story with you here.

For decades “Green Molly” has taken on plastic pollution. Why is this problem so personal to you?

Plastics and their role on the environment have been a lifelong passion. When I was in elementary school, I took a field trip to the Monterey Bay Aquarium where I saw an exhibit on plastic waste in the ocean. Ever since I have been a fanatic on addressing plastic pollution.

What I learned through my undergraduate and graduate coursework was that we are not going to be able to recycle our way out of the global crisis we are facing. We need to figure out something new that will make the difference.

An incredible team of women - left to right: Allison Pieja, Molly Morse, and Anne Schauer-Gimenez

What was your Eureka moment during the development phase of the solution?

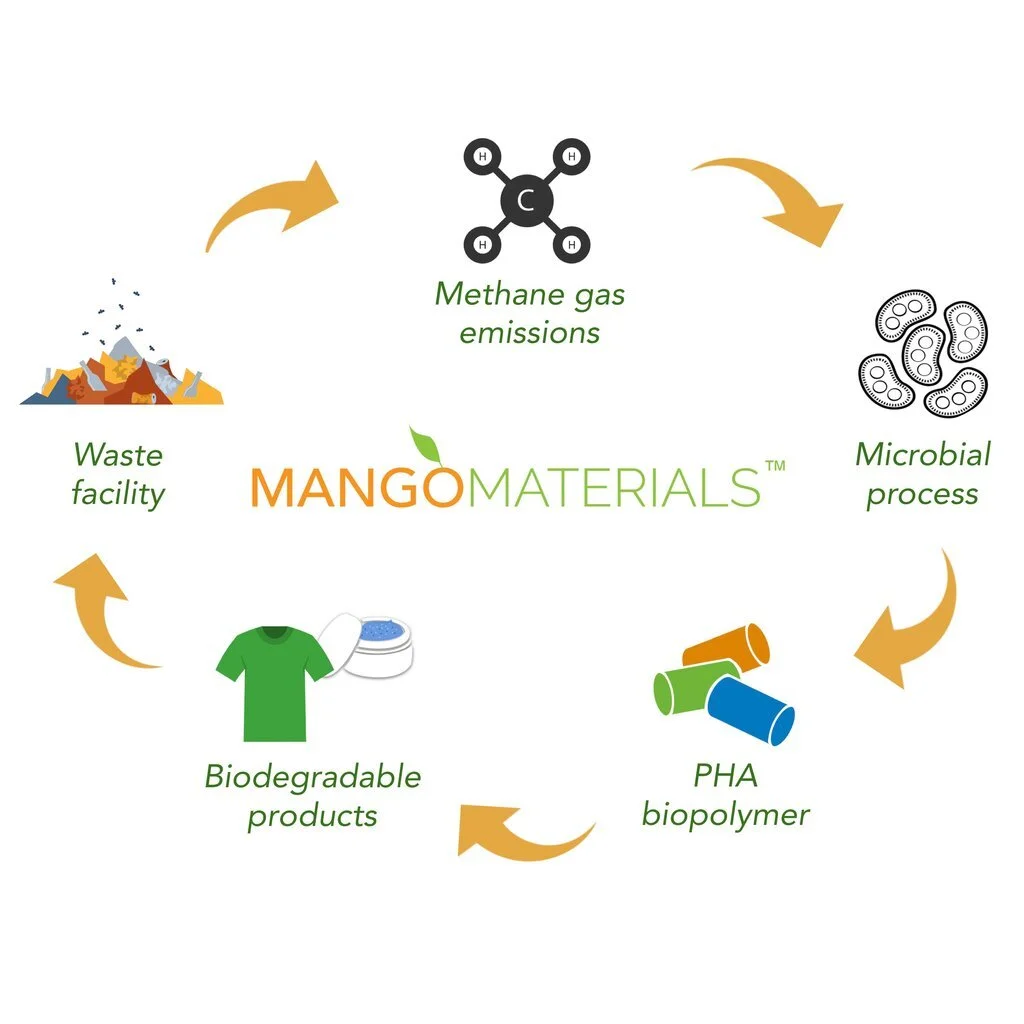

During one of my graduate projects, I was studying a class of biopolymers called PHAs. Traditionally, PHAs are produced by taking natural bacteria, feeding them sugar, and then the bacteria produce PHA as a byproduct. Our project advisor loved the properties of PHA, but the problem was the market was limited, and the sugar needed required large agricultural lands we did not have. We put our heads together and thought, instead of sugar, why not use methane as a feedstock to produce PHA? We did the stoichiometry conversion on a napkin, and it worked! Not only is methane a naturally occurring biproduct, but it is also more cost efficient than sugar and other feedstocks that competing companies are using.

Curious about the process? Check out this video featuring Molly and Mango Materials!

What is being used now and why isn’t it a solution?

Currently, the most widely used biopolymer on the market is PLA. The problem is, PLA will usually only break down in industrial composting facilities. It needs high heat and high pressure to biodegrade. This is not going to solve our environment problem because materials frequently do not end up in a composting facility. Since PLA products cannot biodegrade in the ocean or on land without special treatment, they can inadvertently make plastic pollution worse.

How is your solution better for the environment?

What is unique about our solution is its end-of-life process. Our PHA biodegrades naturally, unlike traditional PLA material. For example, if we make fibers for apparel and some of the fibers come off during laundering and end up in the wastewater treatment plant or the ocean, our material is naturally digested. In other words, it will biodegrade and not persist in the environment like other plastics.

These PHA pellets, manufactured by Mango Materials, are ready to be made into biodegradable products!

What is your vision for the future? How will you evolve Mango to address plastic pollution at scale?

Right now, we are focused in the San Francisco Bay Area. We are looking to scale to the next stage with a bigger plant in California to produce more material.

Currently we are focused on two specific end-use applications in beauty packaging and fashion products. However, longer-term, we want to produce plastic bags, garbage bags, and other major use plastics, but to do that we have to scale up to keep the manufacturing costs low. Wherever there is waste methane we can produce PHA. This opens the opportunity for jobs, economic resiliency, and will revolutionize how plastics are made.

A green and sustainable cycle

Why is Reaction the right partner for Mango Materials?

Reaction was a perfect fit for us because of their large and diverse network of influential leaders all over the world. Their global expertise and perspectives are exactly what we need as we look to scale. We used to be focused in our lab to get our solution off the ground, but now we are focused on commercialization and Reaction has been a big support in getting us there.

For further information about Reaction please visit the Reaction website at reaction.global or contact the Reaction team at change@reaction.global.

About the Author

Samantha Allen is a Reaction Fellow from Chicago, Illinois.

About Reaction

Reaction is about creating exponential change. We are a global community of entrepreneurs, investors and executives who share a vision for a world where innovation can meaningfully change more lives in less time. Why now? Because more innovations will be created in more countries and more industries over the next decade than in the previous 50 years. Many will offer the potential to solve global issues. But will fail to reach the markets they could have benefited most. Reaction was founded by a global team of Stanford alumni who united to solve this problem together. Our mission is to measurably improve one billion lives, within a decade, by scaling innovations that will change the world.